Industrial Air Separation Plants

Price 10000000.0 INR/ Unit

Industrial Air Separation Plants Specification

- Automation Grade

- Fully Automatic

- Temperature Range

- -196C to ambient

- Production Capacity

- Customizable as per requirement

- Frequency

- 50/60 Hz

- Model No

- IASP Series

- Driven Type

- Electric

- Usage & Applications

- Production of oxygen, nitrogen, argon for industrial processes

- Efficiency (%)

- Up to 99.7%

- Accessories

- Compressors, valves, instrumentation

- Installation Guideline

- Supervised by qualified engineers

- Speed

- Regulated via control system

- Motor Power

- Variable up to 800 kW

- Type

- Industrial Air Separation Plant

- Material

- Stainless Steel, Carbon Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC based

- Drive Type

- Electric

- Voltage

- 380440 V

- Power

- 1002000 kW (depending on model)

- Weight (kg)

- 20000150000 kg

- Dimension (L*W*H)

- Variable based on capacity

- Color

- Silver/Grey

- Capacity

- 505000 Nm/hr

- Features

- Energy efficient, High purity separation, Low maintenance

- Machine Type

- Cryogenic Air Separation Unit

- Power Consumption

- Optimized for industrial use

- Surface Finish

- Polished/Corrosion Resistant

- Maintenance Interval

- 12 months

- Service Support

- On-site commissioning and training

- Service Life

- 15+ years

- Operating Pressure

- Up to 6 MPa

- Alarm System

- Integrated safety alarms

- Design Standard

- Complies with DIN/ASME standards

- Export Markets

- Worldwide

- Noise Level

- Low (as per industrial standards)

- Gas Purity

- Oxygen up to 99.7%, Nitrogen up to 99.999%

- Cooling System

- Water/Air cooled

- Pre-cooling Option

- Available

Industrial Air Separation Plants Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- New Delhi, Mumbai

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 90 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Packaging

- Main Export Market(s)

- Western Europe, Middle East, Africa, Central America, North America, South America, Eastern Europe

- Certifications

- CE & ISO Certified

About Industrial Air Separation Plants

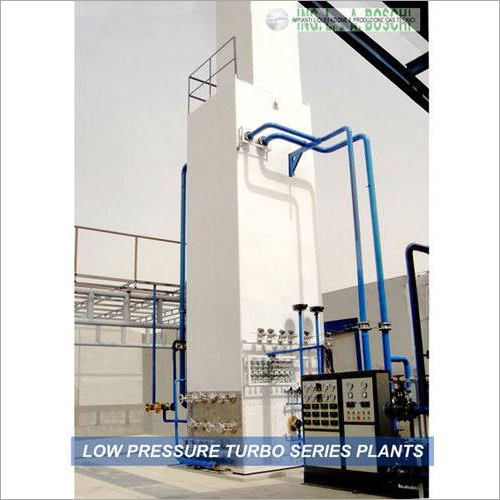

Industrial Air Separation Plants

Universal Industrial Plants Mfg. Pvt. Ltd. manufactures and supplies Low pressure Air Separation Plant, Oxygen Plant and Nitrogen Plant of different sizes, right from 20 m3/hour to 500 m3/hour, for instance Air Separation Plant, Cryogenic Tonnage Oxygen Plant, Cryogenic Tonnage Nitrogen Plant and Liquid Oxygen Nitrogen Plant. ING.Our company collaborated with L. A. Boschi of Italy to share the design and technology for the mentioned plant.

Quality: UNIVERSAL BOSCHI is an ISO 9008:2015 and CE certified company that guarantees the quality of industrial plants delivered to the customers.

Main Performance of The Plant:

- Capacity Range (Cu. Mtr/hr): 50 to 50.000m3/hr

- Nitrogen Pressure out of Column (bar): 7 bar

Main Equipment:

- Pre- Cooling system

- Universal Boschi Purifier

- Fully Automatic Rotary air compressor

- Air separation Unit

|

PRODUCTION |

UBT-400 |

|

OXYGEN (NM3/HR) CYLINDERS PER DAY |

400 |

|

1600 |

|

|

OXYGEN CYLINDER PRESSURE 150BAR TO 200BAR |

|

|

NITROGEN NM3/HR |

400 |

|

OXYGEN PURITY-% |

99.7 |

|

NITROGEN (%) |

99.9 |

Advanced Gas Purity and Capacity

Engineered for both oxygen and nitrogen production, the IASP Series delivers exceptional purityup to 99.7% for oxygen and 99.999% for nitrogen. Capacities are customizable, ranging from 50 to 5000 Nm/hr, meeting diverse industrial needs. The plant accommodates a wide range of requirements for chemical processes, metallurgy, and more.

Comprehensive Automation and Safety

These air separation plants feature a fully automatic, PLC-controlled system for consistent performance and operational ease. Integrated safety alarms provide real-time monitoring, ensuring plant and personnel safety. All systems comply with leading international standards, guaranteeing reliable and secure operations.

Optimized Energy Efficiency and Low Maintenance

IASP Series plants are designed with efficiency and longevity in mind. Optimized power consumption (1002000 kW) and 12-month maintenance intervals significantly reduce operational costs. This, combined with robust materials and corrosion-resistant surfaces, contributes to a service life exceeding 15 yearsideal for continuous industrial operation.

FAQs of Industrial Air Separation Plants:

Q: How does the IASP Series Air Separation Plant achieve high gas purity levels?

A: The plant employs advanced cryogenic processes and precise controls, achieving oxygen purity up to 99.7% and nitrogen up to 99.999%. PLC-based automatic systems regulate temperature, pressure, and flow, optimizing the separation process for high-quality output.Q: What is involved in the on-site commissioning and training service?

A: Qualified engineers supervise installation and commissioning, ensuring the system operates as designed. Comprehensive training is provided to client personnel, covering operation, maintenance, and safety procedures for reliable, autonomous plant management.Q: When should routine maintenance be carried out on the air separation unit?

A: Routine maintenance is recommended every 12 months, ensuring longevity and optimal performance. Maintenance covers inspection of compressors, valves, instrumentation, and control systems, with detailed guidelines provided during commissioning.Q: Where can these industrial air separation plants be installed?

A: IASP Series plants are suitable for a variety of industrial sites worldwide, including manufacturing, metallurgy, chemical processing, and medical gas supply. Export services ensure support for global installations, tailored to local standards and site needs.Q: What are the benefits of the integrated safety alarm system?

A: The safety alarm system offers continuous monitoring of critical plant parameters, instantly alerting operators to any irregularities. This helps prevent equipment damage, enhance personnel safety, and minimize costly downtime.Q: How is pre-cooling incorporated into the operational process?

A: A pre-cooling option is available, lowering inlet air temperature before separation. This enhances overall efficiency and improves gas purity, especially critical for demanding industrial applications.Q: What are the main advantages of choosing the IASP Series Air Separation Plant?

A: Key advantages include customizable production capacity, high efficiency, fully automatic operation, robust construction, global support, low noise levels, and minimal maintenance requirements. These features collectively deliver long-term, reliable performance for industrial gas production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Separation Plants Category

Cryogenic Air Separation System

Minimum Order Quantity : 1 Unit

Surface Finish : Other, Polished/Brushed Stainless Steel

Automatic Grade : Automatic

Control System : Other, PLC Controlled

Machine Type : Industrial Air Separation Plant

Automation Grade : Automatic

Cryogenic Air Separation Plant

Minimum Order Quantity : 1 Unit

Surface Finish : Other, Anticorrosive, polished

Automatic Grade : Automatic

Control System : Other, PLC Controlled

Machine Type : Industrial Gas Plant

Automation Grade : Fully Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese